When most people think of aerospace, they picture enormous engines roaring to life or satellites floating silently in space. But every successful flight depends on thousands of carefully made parts you’ll probably never see. And over the last decade, Aerospace parts manufacturing companies in India have quietly stepped up to become some of the most reliable suppliers of those critical components.

These companies aren’t just catching up with their international peers. In many cases, they’re leading the way with fresh ideas and smarter processes. Let’s look at what’s driving that progress, and why it matters to the global aerospace industry.

How India Went from Outsourcing Hub to Innovation Center?

It wasn’t long ago that India was mainly known for providing simpler aerospace parts, standard brackets, fasteners, or basic assemblies. Today, the picture has changed. Some of the most advanced components in modern aircraft are built here.

What caused this transformation? For starters, companies invested heavily in the right equipment. CNC machines with five or more axes, autoclaves for curing composites, precision measurement labs, all have become common in the country’s top facilities. But it isn’t just hardware. There’s been a shift in mindset too.

You can feel it when you talk to teams in these factories. They’re proud of what they make. They want their work to stand alongside the best in the world.

The Composite Revolution

Ask any aerospace engineer what keeps them up at night, and weight will come up fast. Every kilogram saved means better fuel efficiency and more room for payload. That’s why composites, materials that are strong but lightweight, are such a big deal.

Leading Aerospace parts manufacturing companies in India have built serious expertise here. They work with carbon-fiber layups, honeycomb structures, and advanced resin systems. Many now run their own autoclaves and clean rooms, meeting the same standards as top suppliers in Europe or the US.

These materials aren’t just a trend. They’re now essential to almost every new aircraft and satellite design.

3D Printing Changes the Game

A decade ago, metal 3D printing in aerospace was mostly an experiment. Today, it’s a standard tool for prototyping, and increasingly, for final production.

Some Indian manufacturers were early adopters. They saw that additive manufacturing could reduce waste and make shapes you couldn’t produce any other way. Instead of cutting away material, you build parts layer by layer.

This approach means you can combine multiple components into a single piece, reduce weight, and simplify assembly. It’s efficient, and it lets engineers design without being boxed in by old manufacturing limits.

Smarter Production with Digital Tools

The most impressive factories I’ve seen don’t just have shiny machines. They have data flowing everywhere.

Industry 4.0, using sensors and software to monitor production in real time, is alive and well among India’s best aerospace suppliers. Machines track tool wear and adjust automatically. Inspection results get logged instantly. Engineers can see dashboards of every process step.

This isn’t technology for its own sake. It’s how you catch problems before they become expensive. And it’s a big reason why these companies can meet tight delivery schedules with fewer hiccups.

Precision You Can Trust

In aerospace, “close enough” is never good enough. A turbine blade or a critical fastener has to meet exact tolerances, sometimes within microns.

That’s where Indian manufacturers have invested the most. Multi-axis CNC machines, laser scanners, coordinate measuring machines, these are now standard tools in many workshops.

But tools alone don’t guarantee quality. The best companies spend just as much time training people. Skilled machinists and inspectors make the difference between a part that passes and one that performs for years.

Surface Treatments That Matter

It’s easy to forget that once a part comes off the machine, it still needs finishing. Aerospace parts face heat, corrosion, and fatigue that would destroy ordinary components.

Companies here have learned to master special processes:

- Shot peening to improve fatigue life

- Coatings that resist high temperatures

- Chemical treatments that protect against corrosion

These steps are often audited by customers and independent agencies. Passing those tests shows you’ve reached a global standard.

A Supply Chain That Runs Smoothly

One area where Indian firms have quietly excelled is supply chain management.

Aerospace programs have long timelines, but they also need predictable deliveries. The best manufacturers have learned how to forecast demand, keep materials ready, and stay transparent about what’s happening at every stage.

That reliability is why you see Indian-made parts on major aircraft platforms and satellite programs. When customers know they can count on you, they come back.

Not Just Vendors, Partners in Design

Another big shift? More companies have moved upstream. Instead of waiting for blueprints, they work side by side with customers to refine designs.

This approach pays off. When a supplier helps tweak a part so it’s easier to manufacture, or lighter without losing strength, everyone benefits. Costs drop, and performance improves.

This culture of collaboration has been a hallmark of many of the best Aerospace parts manufacturing companies in India. It’s one reason their customers tend to stick around.

Sustainability and Responsibility

Aerospace companies face growing pressure to reduce their environmental impact. The same is true for their suppliers. Leading Indian manufacturers have embraced this challenge. Some run solar power systems to cut carbon footprints. Others have found safer chemicals for cleaning and coating parts. Waste recycling and water conservation are becoming routine.

Sustainability isn’t a side project anymore, it’s part of how you earn business.

Investing in People

No matter how much automation you add, skilled workers are still the backbone of quality. That’s why these manufacturers focus on training. They set up in-house academies. They partner with universities. They run apprenticeships for young machinists and engineers. The result is a workforce that knows what’s at stake, and takes pride in meeting those standards.

Certifications That Prove Capability

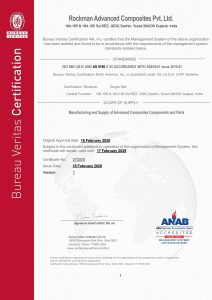

Of course, none of this counts without certification. Aerospace customers want evidence that suppliers can deliver every time. You’ll find AS9100 quality systems, NADCAP accreditations, and ISO standards across India’s top aerospace facilities.

Real-World Results

All this investment and focus has paid off. Today, you’ll find Indian-made parts in:

- Commercial aircraft flying across continents

- Satellites orbiting the earth

- Fighter jets and defense platforms

- Critical subsystems for global OEMs

The fact that some of the biggest names in aerospace now source from India says everything.

Final Thoughts

When you look at what’s changed, it’s clear: Aerospace parts manufacturing companies in India are no longer just options for low-cost work. They’re respected partners capable of solving complex challenges and delivering parts that meet the highest standards.

If you’re sourcing aerospace components, it’s worth paying close attention to what these companies offer. Whether it’s additive manufacturing, composite expertise, or smart production, innovation is alive and well here.