Selecting the right aerospace component manufacturing company is one of the most critical decisions for businesses in aviation, defense, and space exploration. Every component, whether it’s a precision-machined part or an advanced composite structure, must meet the highest standards of reliability, performance, and safety. With stringent regulations, rapidly evolving technologies, and growing demand for innovation, companies need to partner with manufacturers that not only deliver precision but also act as long-term collaborators in driving progress.

At Rockman Advanced Composites, we understand the importance of making informed decisions when it comes to choosing a manufacturing partner. Below are the key aspects professionals and decision-makers should evaluate to ensure they select a partner that delivers on both quality and innovation.

-

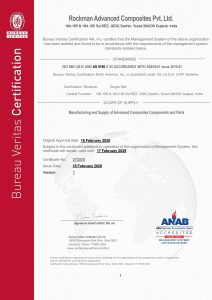

Evaluate Industry Certifications and Compliance

The aerospace sector is governed by strict international standards. Certifications are not just badges of credibility; they prove that a company follows rigorous processes in design, production, and testing. For instance, AS9100 certification is widely regarded as the benchmark for aerospace quality management systems.

When considering a manufacturer, verify if they hold relevant certifications and compliance approvals. This ensures that every component produced adheres to industry norms, minimizing risks and ensuring seamless integration into larger systems. A company committed to compliance is one that prioritizes safety, accountability, and continuous improvement.

-

Focus on Technological Capabilities

Innovation in aerospace depends heavily on advanced technology. From computer-aided design and simulation tools to automated machining and composite fabrication, the right technologies enable manufacturers to deliver high-performance parts with consistency.

Look for a company that invests in state-of-the-art machinery and software. For example:

- Composite material expertise for lightweight yet durable parts.

- 5-axis CNC machining for precision and efficiency.

- Additive manufacturing capabilities for prototyping and customized solutions.

- Non-destructive testing for ensuring defect-free products.

The right mix of technologies not only enhances production efficiency but also ensures that new designs can be tested and refined quickly, reducing time-to-market.

-

Consider Experience in Aerospace Programs

Experience in handling complex aerospace programs plays a vital role in the credibility of a manufacturing partner. A company with a proven track record in delivering components for commercial aircraft, defense systems, or space missions brings more than technical expertise—it brings reliability, problem-solving abilities, and the ability to manage large-scale projects.

Ask potential partners about their history of working with aerospace primes or tier-one suppliers. Their portfolio will demonstrate their ability to meet strict timelines, work with cutting-edge designs, and maintain high quality standards across diverse projects.

-

Innovation and R&D Commitment

The aerospace industry thrives on continuous innovation. A reliable manufacturer should not only execute existing designs but also contribute to improving them. This is possible only if the company invests consistently in research and development.

Manufacturers with strong R&D teams often collaborate closely with clients to develop lightweight materials, reduce costs, and improve fuel efficiency without compromising safety. This collaborative approach leads to long-term benefits for both parties, making the manufacturer a true innovation partner rather than just a supplier.

-

Scalability and Production Capacity

Whether you need a limited batch of prototypes or a large production run, scalability is essential. Aerospace programs often start with small-scale production for testing and then ramp up to larger quantities once approved. A dependable manufacturer should have the flexibility to scale operations without affecting timelines or quality.

Check whether the company has robust infrastructure, dedicated assembly lines, and enough workforce to handle variations in production volume. This ensures your projects remain on schedule even when requirements increase.

-

Quality Assurance and Testing Rigor

Every aerospace component must perform flawlessly under extreme conditions. That’s why testing and validation are non-negotiable. A strong manufacturing partner will have well-defined quality assurance processes that cover every stage, from raw material inspection to final product validation.

Important factors to assess include:

- Availability of in-house testing labs.

- Non-destructive testing techniques like ultrasonic or X-ray inspections.

- Traceability systems for raw materials and finished components.

- Stringent checks for dimensional accuracy and performance under stress.

Companies with robust quality assurance practices minimize the risk of in-service failures, protecting both end-users and their own reputation.

-

Supply Chain and Reliability

In aerospace, delays in one part of the supply chain can disrupt entire projects. A manufacturing partner with strong supplier relationships and robust logistics ensures timely delivery of raw materials and finished products.

Evaluate how the company manages its supply chain, from sourcing advanced materials to delivering completed assemblies. Look for transparency, reliability, and the ability to mitigate risks such as material shortages or geopolitical disruptions.

-

Customization and Collaboration

No two aerospace projects are alike. Each has unique requirements, whether related to weight reduction, aerodynamics, or durability. A capable manufacturer should be able to tailor solutions to specific needs rather than offering one-size-fits-all products.

Collaboration is equally important. Manufacturers that work closely with clients during design, prototyping, and testing phases foster stronger partnerships. This co-engineering approach ensures that components not only meet technical specifications but also align with the broader goals of the aerospace program.

-

Global Reach with Local Support

Aerospace is a global industry, but local support still matters. Companies with international exposure and a wide network bring best practices from different markets while offering accessible, responsive support locally.

When selecting a partner, consider their ability to serve both global and regional requirements. This balance ensures you benefit from innovation and scale while enjoying the convenience of localized service.

-

Financial Stability and Long-Term Reliability

Aerospace programs often span years, if not decades. Partnering with a financially stable manufacturer reduces the risk of disruptions during critical stages of your project. Stability also indicates a company’s ability to continually invest in new technologies, infrastructure, and workforce development.

Check the company’s financial background and long-term growth strategy. A forward-looking organization is more likely to remain a trusted partner for years to come.

Why Rockman Advanced Composites Stands Out

At Rockman Advanced Composites, we embody all the qualities that define a trusted aerospace component manufacturing company. Our commitment to precision, innovation, and long-term collaboration has earned us recognition among industry leaders.

- Advanced Technology: We specialize in composite manufacturing, CNC machining, and advanced material processing to deliver world-class components.

- Proven Experience: Our portfolio includes partnerships with major aerospace programs where we have consistently delivered reliable and high-performance solutions.

- Focus on Innovation: With a strong R&D foundation, we collaborate with clients to design and deliver next-generation aerospace components.

- Robust Quality Systems: Our testing and validation procedures ensure every component meets international safety and performance standards.

- Scalability and Reliability: From prototypes to mass production, we provide seamless scalability while maintaining uncompromised quality.

By combining expertise with forward-looking innovation, Rockman Advanced Composites ensures that aerospace companies receive more than just components—they gain a partner committed to shaping the future of aviation and space technologies.

Final Thoughts

Choosing the right aerospace component manufacturing company is about more than comparing price points. It requires evaluating technical capabilities, quality assurance, innovation culture, and long-term reliability. A strong partner can help organizations not only meet immediate project requirements but also push the boundaries of what’s possible in aerospace engineering.

Rockman Advanced Composites continues to stand at the forefront of quality and innovation, supporting industry professionals and organizations that aim to redefine aerospace excellence.