If you run trains for a living, or support the companies that do, you already know something crucial: details matter. A lot. Every carriage, bogie, axle, and bracket plays a role in keeping passengers safe and cargo moving.

When a component fails, it’s not a small issue. It can trigger service delays, damage your reputation, and even endanger lives. That’s why picking the right railway component manufacturers in India is such a big decision. It’s about more than price or lead times. It’s about trust.

Let’s walk through what separates reliable suppliers from risky ones, and how you can make a confident choice.

Why You Can’t Afford to Cut Corners

Sure, budgets are tight in rail operations. Every purchase gets scrutinized. But a cheap component is often the most expensive mistake you’ll ever make. Think about it. One bearing fails early. A brake system doesn’t engage precisely. Suddenly, you’re dealing with:

- Emergency repairs

- Delayed schedules

- Complaints piling up

- Regulatory investigations

- Rising insurance costs

All because a part wasn’t up to standard. Quality isn’t a luxury. It’s the backbone of safe, efficient service. When you look for suppliers, that has to come first.

India’s Evolving Rail Manufacturing Landscape

India has long been a key rail market. But over the last two decades, it’s transformed into a global hub for quality manufacturing.

Today, many railway component manufacturers in India operate facilities with:

- Precision CNC machines

- Robotic welding systems

- Modern testing labs

They’re delivering parts that meet the same benchmarks as European or American suppliers. That said, not all companies have kept pace. Some still rely on older equipment and inconsistent processes. That’s why you can’t skip due diligence.

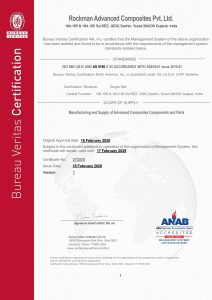

Certifications: The First Line of Defense

When you’re evaluating a supplier, certifications are a quick way to separate serious contenders from everyone else. Look for:

- ISO 9001 for general quality management

- IRIS, which is specific to railway suppliers

- ISO 14001 for environmental management

These credentials show the company has systems in place to catch mistakes. They don’t guarantee perfection, but they’re a strong start. If a manufacturer dodges questions about certification, or shows you outdated documents, tread carefully.

Materials: The Foundation of Every Good Part

It’s easy to assume a part will perform if it looks right. But performance starts with materials you can trust. Ask questions:

- Where do you source your raw materials?

- How do you test batches for composition and strength?

- Can you trace each lot back to the supplier?

Reputable companies will have documented answers. If a manufacturer shrugs or says, “We’ve never had a problem,” that’s a red flag.

Process Control: Where Reliability Comes From

Consistency isn’t magic, it’s a product of clear processes.

The best railway component manufacturers in India track every production step. You’ll often see:

- Documented procedures

- In-process checks instead of relying only on final inspection

- Digital records of dimensions, temperatures, and machine settings

This discipline ensures every part meets spec. It’s how they deliver repeatable quality, order after order.

Testing: It’s Not Optional

Testing isn’t something to rush through. It’s proof your supplier stands behind their work. Ask to see their process. Serious manufacturers will show you:

- Dimensional inspections with calibrated tools

- Load testing to simulate real-world conditions

- Non-destructive testing for hidden cracks

They might even invite you to watch. That’s usually a good sign.

Skilled Teams Make the Difference

Machines help. But humans catch problems that sensors can miss. When you tour a facility, or join a video call, pay attention to the people. Do they look engaged? Do they know their craft? Companies with stable, skilled teams often have fewer issues over time. High turnover is usually a warning.

Traceability

Even great suppliers can have an occasional defect. When it happens, you need to trace it fast. Reliable manufacturers keep detailed records that link every part to:

- Raw material batches

- Machines and operators

- Inspection data

This traceability protects you when something goes wrong. It also helps maintain compliance with regulators.

When You Need Custom Parts

Many rail operators need components that aren’t off-the-shelf. Maybe it’s a part for an older system or something adapted for local conditions. Good railway component manufacturers in India don’t shy away from these projects. They’ll help you:

- Review designs for manufacturing feasibility

- Prototype quickly

- Tweak dimensions to improve fit and function

Pricing

It’s tempting to jump at the lowest quote. But a cheap price sometimes hides problems, cheaper alloys, skipped inspections, delayed deliveries. A trustworthy supplier explains:

- What the price includes

- What materials will be used

- What certifications are built into the cost

- How shipping and packaging work

If a bid feels vague, ask more questions.

What About Support After Delivery?

Even with rigorous processes, surprises can happen. The real test is what happens next. Ask suppliers:

- How do you handle warranty claims?

- What’s your timeline for replacements?

- Will you help us find the root cause?

Partners who care about long-term relationships won’t avoid these topics.

Visiting the Factory

Nothing replaces seeing a site firsthand. If you can, walk through the shop floor. Look for:

- Clean work areas

- Clearly marked materials

- Staff who can explain what they’re doing

- A sense of order, not chaos

These details tell you whether quality is real or just a promise.

Protecting Your Designs

Rail operators often share proprietary specs. Make sure your intellectual property is safe. Good suppliers:

- Sign NDAs without fuss

- Store data securely

- Restrict access to drawings

If someone hesitates on this, ask yourself why.

Building Long-Term Partnerships

The best results happen when you treat suppliers as partners. Over time, trust builds. You get:

- Faster response times

- Flexibility in busy seasons

- Insights about design improvements

Final Thoughts

In rail, everything depends on trust. You trust your components to perform day after day, year after year. That’s why choosing the right railway component manufacturers in India is one of the most important decisions you’ll make. Take the time to ask questions. Visit factories. Review documentation. The effort you invest now can prevent problems later, and protect your passengers, your colleagues, and your reputation.