Renewable energy is quickly becoming the cornerstone of sustainable development across the globe. As the world seeks cleaner, more efficient ways to generate power, industries have begun to shift towards alternative energy sources such as solar, wind, hydro, and geothermal. One key element in this revolution is the role of advanced materials, specifically composites. The future of renewable energy composite manufacturing is set to play a significant part in shaping the next generation of energy technologies, offering innovative solutions that are lightweight, durable, and environmentally friendly.

In this blog, we’ll delve into the exciting future of renewable energy composite manufacturing, explore the latest innovations in this field, and highlight their applications in the renewable energy sector. For businesses and professionals in the energy and manufacturing industries, understanding these developments can open doors to new opportunities, performance improvements, and more efficient designs.

What are Renewable Energy Composites?

At their core, renewable energy composites are materials made from two or more constituent components that have distinct physical or chemical properties. These composites are specifically designed to enhance the performance of renewable energy systems, particularly in areas where traditional materials might not be as effective. Common composite materials include carbon fiber, glass fiber, natural fibers, and resins, each offering unique characteristics that make them ideal for specific applications.

These materials are already in use across various renewable energy technologies, including wind turbines, solar panels, energy storage systems, and even in bioenergy applications. Their lightweight nature and strength enable greater energy efficiency, durability, and cost-effectiveness—three of the most critical factors in the renewable energy industry.

Innovations in Renewable Energy Composite Manufacturing

As the demand for renewable energy solutions continues to grow, so does the need for more advanced composite materials and manufacturing techniques. Several innovations are shaping the future of renewable energy composite manufacturing, and industry experts are focusing on key developments to push the boundaries of what’s possible. Let’s explore some of the latest breakthroughs:

-

Advanced Carbon Fiber Composites

Carbon fiber composites are renowned for their high strength-to-weight ratio, which makes them ideal for wind turbine blades and solar panels. The future of carbon fiber composites in renewable energy manufacturing lies in improving the material’s performance while reducing production costs. Manufacturers are exploring new methods of carbon fiber production that use sustainable practices, such as recycling carbon fiber from retired aircraft or automotive parts. These innovations are not only environmentally friendly but also offer a cost-effective way to expand the use of carbon fiber composites in renewable energy applications.

-

Bio-based and Eco-friendly Composites

The growing trend toward sustainability has led to the development of bio-based composites that use natural fibers such as hemp, jute, or flax. These bio-composites are an eco-friendly alternative to traditional materials and are increasingly being used in wind turbine blades, solar panel enclosures, and other renewable energy components. Bio-based composites offer several advantages, including lower environmental impact during production, reduced carbon footprint, and biodegradability at the end of their life cycle.

Manufacturers are also experimenting with new resin systems, such as bio-resins made from renewable resources, which complement bio-based fibers to produce entirely sustainable composite materials.

-

Lightweight and High-Performance Composites for Energy Storage Systems

Energy storage systems are critical for addressing the intermittency challenges of renewable energy. To optimize energy storage, lightweight and durable composite materials are essential for constructing batteries, capacitors, and other storage systems. The next generation of composites will focus on enhancing the thermal and electrical properties of materials while ensuring that they remain lightweight and efficient. Advances in composite materials for energy storage could dramatically improve the performance of electric vehicles, grid storage, and off-grid renewable energy systems.

-

Smart Composites with Embedded Sensors

The integration of smart sensors into composite materials is another promising innovation. These sensors can monitor temperature, stress, and strain in real-time, providing valuable data that can improve the performance and maintenance of renewable energy systems. For instance, in wind turbine blades, smart composites could detect early signs of damage or wear, allowing for proactive maintenance and reducing downtime. In solar panels, embedded sensors could monitor energy output efficiency, ensuring that systems operate at peak performance.

-

Recycling and End-of-Life Management of Composites

As the renewable energy sector grows, the challenge of recycling composite materials becomes increasingly important. Traditional composites, particularly those used in wind turbine blades and solar panels, are often difficult to recycle, leading to environmental concerns. In response, researchers are developing new methods for breaking down and reusing composite materials at the end of their life cycle. Innovations in chemical recycling, along with the use of recyclable resins and fibers, are paving the way for more sustainable composite manufacturing in the renewable energy industry.

Applications of Renewable Energy Composites

The use of composites in renewable energy is vast and continues to expand as manufacturing techniques improve and materials evolve. Here are some of the most prominent applications of renewable energy composite manufacturing:

-

Wind Turbine Blades

One of the most prominent applications of composites in renewable energy is in wind turbine blades. Wind turbine manufacturers rely on composites, especially fiberglass and carbon fiber, to create blades that are both lightweight and strong. Composites enable wind turbine blades to be longer and more efficient, allowing for better energy capture from wind. As wind energy production continues to grow, there is a strong emphasis on developing stronger, lighter, and more durable composite materials that can withstand extreme weather conditions and reduce the environmental impact of wind farms.

-

Solar Panels and Solar Thermal Collectors

Composites are also playing a key role in improving the efficiency of solar panels and solar thermal collectors. The lightweight nature of composites reduces the overall weight of solar panel systems, making installation easier and more cost-effective. Additionally, composite materials in solar collectors help enhance thermal performance, providing better heat retention and energy efficiency. By incorporating advanced composites, manufacturers can improve the longevity and durability of solar systems while maintaining high performance in harsh environmental conditions.

-

Energy Storage Systems

The integration of composite materials in energy storage systems, such as lithium-ion batteries and supercapacitors, is another critical area where renewable energy composite manufacturing is making a significant impact. Composites can improve the performance of energy storage units by offering lightweight, durable, and thermally stable materials. This innovation is crucial for expanding the use of renewable energy storage in electric vehicles, off-grid systems, and large-scale renewable energy projects.

-

Hydropower and Marine Energy Devices

In the renewable energy sector, hydropower and marine energy devices are another area where composites are gaining traction. Composites are used to create more efficient and durable components for underwater turbines, tidal energy systems, and wave energy converters. The corrosion resistance and strength of composites make them ideal for underwater applications, where they can withstand the harsh conditions of saltwater environments while maintaining optimal performance.

The Road Ahead for Renewable Energy Composite Manufacturing

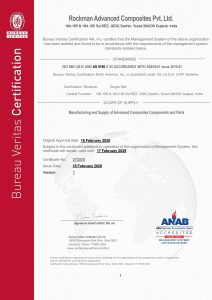

As the renewable energy industry continues to evolve, renewable energy composite manufacturing will play an increasingly important role in driving the sector toward sustainability and efficiency. With advancements in material science, recycling, and manufacturing techniques, composites will become even more integral to renewable energy technologies. As businesses like Rockman Advance Composites continue to innovate, the future of renewable energy will be brighter, more efficient, and, most importantly, more sustainable.

For professionals in the industry, staying up-to-date with the latest developments in composite materials and manufacturing techniques is essential. By embracing new innovations, businesses can not only improve the performance of renewable energy systems but also contribute to the global effort to create a more sustainable future.

In conclusion, the future of renewable energy composite manufacturing is poised to drive significant advancements across the renewable energy sector. With new materials, production methods, and applications, composites will continue to enhance the efficiency, durability, and sustainability of energy systems worldwide.