Automotive parts manufacturers in India play a pivotal role in shaping the nation’s thriving automotive industry. With a robust infrastructure, technological expertise, and a strong focus on quality, these manufacturers are redefining the standards of automotive components across domestic and international markets. Companies are not only delivering precision-engineered components but also integrating innovative materials, advanced manufacturing techniques, and sustainability practices that align with global automotive trends.

India’s automotive sector has emerged as a hub for both original equipment manufacturers (OEMs) and aftermarket suppliers. This dynamic ecosystem has enabled automotive parts manufacturers in India to serve a diverse range of vehicles, including passenger cars, commercial trucks, two-wheelers, and electric vehicles (EVs). The rise of electric mobility, hybrid technologies, and lightweight components has created new avenues for manufacturers to innovate and provide solutions that enhance vehicle performance, fuel efficiency, and safety.

Driving Technological Innovation

The competitive edge of leading automotive parts manufacturers in India lies in their commitment to research and development. Advanced technologies such as robotics, precision machining, additive manufacturing, and automation are increasingly adopted to produce components with higher accuracy, durability, and consistency. High-performance composites, alloys, and polymers are being integrated into components like engine parts, transmission systems, brake assemblies, and suspension systems, ensuring optimal strength-to-weight ratios and long-term reliability.

Manufacturers are also investing heavily in smart manufacturing systems, incorporating IoT and AI-driven monitoring solutions. These systems allow real-time data collection, predictive maintenance, and process optimization, ultimately reducing production costs and enhancing quality assurance. By leveraging these technologies, automotive parts manufacturers in India are not just meeting international quality standards but often exceeding them, positioning themselves as preferred partners for global automotive brands.

Commitment to Quality Standards

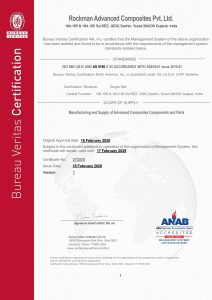

Quality assurance remains a non-negotiable priority for top automotive parts manufacturers in India. Certifications such as ISO/TS 16949, ISO 9001, and various automotive OEM approvals serve as benchmarks for ensuring product reliability and consistency. Rigorous testing protocols, including fatigue testing, thermal analysis, corrosion resistance evaluation, and performance validation under extreme conditions, guarantee that each component performs flawlessly in real-world scenarios.

Companies like Rockman Advanced Composites demonstrate how precision engineering and quality control can coexist with innovative design. By combining advanced composites and lightweight materials with rigorous testing, components achieve superior mechanical properties without compromising on safety or durability. This approach strengthens the trust of automotive OEMs and aftermarket clients alike, ensuring long-term partnerships and repeat business.

Focus on Sustainability and Environmental Responsibility

Environmental responsibility has become an integral part of the automotive supply chain. Leading automotive parts manufacturers in India are increasingly adopting eco-friendly practices, ranging from energy-efficient production processes to the use of recyclable and biodegradable materials. Lightweight composites and advanced polymers are replacing heavier metals, contributing to fuel efficiency and reduced emissions in vehicles.

Manufacturers are also implementing waste reduction strategies, water recycling systems, and renewable energy solutions within their operations. By aligning production processes with sustainable practices, these companies not only support environmental goals but also enhance operational efficiency and cost-effectiveness. Clients increasingly favor manufacturers who demonstrate clear commitment to sustainability, making it a significant differentiator in the competitive automotive market.

Catering to Electric Mobility and Advanced Vehicles

The transition toward electric mobility is reshaping automotive manufacturing worldwide, and India is no exception. Automotive parts manufacturers in India are rapidly adapting to produce components suitable for electric vehicles, hybrid drive trains, and battery management systems. High-voltage connectors, lightweight chassis components, EV battery casings, and thermal management solutions are examples of the innovative offerings emerging from Indian manufacturers.

Rockman Advanced Composites, for instance, specializes in advanced composite solutions that enhance energy efficiency and reduce vehicle weight. Such components are crucial for extending EV range, improving safety, and ensuring performance under diverse operating conditions. By proactively investing in EV-compatible components, Indian manufacturers are establishing themselves as key players in the global electric vehicle supply chain.

Enhancing Global Competitiveness

Indian automotive parts manufacturers have earned recognition on the global stage for their combination of quality, cost-efficiency, and innovation. Exports have seen consistent growth, supplying parts to OEMs in Europe, North America, and Asia. This global competitiveness stems from the ability to adhere to stringent international standards, adapt to rapidly changing automotive technologies, and maintain supply chain efficiency.

Collaborations with international partners, joint ventures, and participation in global trade exhibitions further strengthen the presence of Indian manufacturers. They gain access to emerging technologies, insights into consumer preferences, and opportunities to benchmark against global competitors. As a result, automotive parts manufacturers in India are increasingly positioned as reliable, technologically advanced, and future-ready suppliers.

Customized Solutions for Diverse Applications

Another hallmark of top manufacturers is the ability to provide customized solutions. From high-performance racing components to durable commercial vehicle parts, manufacturers tailor their products to meet the specific needs of clients. Advanced simulation tools, computer-aided design (CAD) systems, and rapid prototyping allow engineers to develop and refine components before large-scale production, reducing development cycles and enhancing performance reliability.

Whether it is precision-engineered engine parts, corrosion-resistant exhaust systems, or lightweight structural components, customization ensures that clients receive products optimized for their vehicle type, operating environment, and performance expectations. This flexibility makes Indian manufacturers invaluable partners for both domestic OEMs and international automotive companies.

Embracing Digitalization and Smart Supply Chains

Digital transformation is revolutionizing the way automotive parts manufacturers in India operate. Smart supply chain management systems, real-time inventory tracking, and data-driven logistics planning improve efficiency, reduce lead times, and minimize disruptions. Integration of Enterprise Resource Planning (ERP) systems with production and quality management ensures seamless coordination across departments, enhancing overall productivity.

By embracing digitalization, manufacturers can also respond quickly to market demands, scale production, and maintain stringent quality standards without delays. This agility is essential in an industry where innovation cycles are accelerating, and customer expectations are continually evolving.

Conclusion

The landscape of automotive parts manufacturing in India is defined by innovation, quality, and adaptability. Manufacturers are not only meeting the current demands of domestic and international markets but are actively shaping the future of mobility. Through technological innovation, sustainable practices, stringent quality assurance, and digital transformation, Indian manufacturers are delivering components that enhance vehicle performance, reliability, and efficiency.

Rockman Advanced Composites exemplifies this progressive approach by combining advanced materials, precision engineering, and innovation to produce automotive components that meet the highest global standards. For industry professionals and automotive enthusiasts, these manufacturers represent the backbone of a rapidly evolving sector, driving India’s reputation as a hub for world-class automotive engineering and manufacturing excellence.