Where strength, efficiency, and innovation define success, composite part manufacturing stands at the forefront of engineering excellence. From aerospace to automotive, energy to defense, precision-engineered composite parts are redefining the boundaries of what’s possible. At Rockman Advanced Composites, we are proud to be at the cutting edge of this transformation—delivering high-performance, lightweight, and durable components that power the future of modern engineering.

The Evolution of Engineering Materials

For decades, metals like steel and aluminium dominated engineering applications. While effective in many respects, these traditional materials carry limitations—particularly in weight-to-strength ratios, corrosion resistance, and design flexibility.

Enter composite materials—engineered combinations of two or more constituent materials with vastly different properties, resulting in products that are lighter, stronger, and more versatile. Fiber-reinforced composites, such as carbon fiber-reinforced polymer (CFRP) and glass fiber-reinforced polymer (GFRP), offer unmatched advantages across a wide range of industries.

But the true revolution lies not just in the material itself, but in the precision composite part manufacturing techniques that turn raw fibers and resins into game-changing components.

Understanding Composite Part Manufacturing

Composite part manufacturing is a highly specialized process that involves layering and curing fibers in a polymer matrix to produce parts with exacting performance characteristics. The process requires meticulous control over orientation, temperature, pressure, and curing cycles to achieve optimal strength and integrity.

At Rockman Advanced Composites, we employ a variety of advanced manufacturing methods, including:

- Autoclave Molding

- Resin Transfer Molding (RTM)

- Vacuum-Assisted Resin Infusion

- Prepreg Layup and Curing

- Filament Winding

Each method is carefully selected based on the application, material type, and required specifications—ensuring every composite component we deliver meets the highest standards of performance and precision.

The Role of Precision in Composite Manufacturing

Precision isn’t just a value—it’s a necessity. Whether crafting aerospace wing components or automotive structural panels, the slightest variation in composite structure can lead to significant performance discrepancies.

At Rockman Advanced Composites, precision composite part manufacturing is achieved through:

- CAD/CAM-Integrated Tooling Design

- Automated Fiber Placement (AFP)

- Advanced Inspection and Testing Systems

- Tight Process Control in Clean room Environments

This exactitude ensures that every composite part functions exactly as designed—offering consistent, repeatable results in mission-critical applications.

Industry Applications: Where Innovation Takes Shape

-

Aerospace and Defense

In aerospace, every gram counts. Composite materials reduce air frame weight, enhance fuel efficiency, and improve payload capacity. Composite part manufacturing enables the production of complex aerodynamic shapes that traditional materials cannot match.

Defense sectors also benefit from composites’ high strength-to-weight ratios, stealth capabilities, and resistance to extreme environments.

-

Automotive and Transportation

The global shift toward electric vehicles (EVs) and fuel efficiency makes lightweight design a top priority. Composites allow manufacturers to lower vehicle weight without compromising safety. Rockman precision-manufactured composites are used in structural components, interior panels, and battery enclosures.

-

Industrial and Energy

Composite parts play a critical role in the renewable energy sector—particularly in wind turbine blades, which require long, durable, and lightweight structures. In industrial applications, composite housings and components resist corrosion, withstand extreme loads, and improve operational lifespan.

-

Medical and Sports Equipment

In fields where ergonomics, strength, and reliability matter, such as prosthetics, wheelchairs, and high-performance sports equipment, composite part manufacturing allows engineers to design components with exacting detail and performance tuning.

Sustainability and Environmental Impact

One of the unsung benefits of composite part manufacturing is its contribution to sustainable engineering. By reducing weight in transportation and machinery, composites cut fuel consumption and greenhouse gas emissions. Additionally, ongoing innovations in recyclable and bio-based composites are opening new doors for green manufacturing.

At Rockman Advanced Composites, sustainability is embedded in our R&D, with focus areas including:

- Recyclable thermoplastic composites

- Natural fiber reinforcements (e.g., flax, hemp)

- Low-energy curing systems

- Waste reduction through precise cutting and nesting software

Innovation at Rockman Advanced Composites

Innovation is at the core of what we do. With a strong commitment to research, quality, and customization, we offer a holistic approach to composite part manufacturing—from concept to production.

Our competitive edge includes:

- State-of-the-art manufacturing facilities equipped with autoclaves, clean rooms, CNC machines, and robotic layup systems

- Collaborative engineering support from concept development to final testing

- Stringent quality assurance protocols including NDT (non-destructive testing), X-ray analysis, and ultrasonic inspection

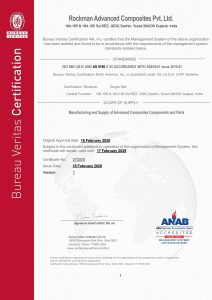

- Certifications and compliance with global standards such as AS9100D, ISO 9001, and IATF 16949

Future Trends in Composite Part Manufacturing

The future of composite manufacturing is being shaped by some transformative trends:

-

Automation and Robotics

Automated fiber placement and robotic systems are reducing lead times and minimizing human error, enabling faster production with higher consistency.

-

3D Printing with Composites

Additive manufacturing with composite filaments is beginning to disrupt prototyping and low-volume production, opening up a world of complex geometries and customization.

-

Digital Twins and Smart Manufacturing

Using real-time data from embedded sensors, manufacturers can now monitor the health of composite parts throughout their lifecycle, optimizing maintenance and improving design iterations.

-

Next-Gen Materials

Research is intensifying around graphene-reinforced composites, nanocomposites, and self-healing polymers, which promise even higher strength and functionality.

Why Choose Rockman Advanced Composites?

With over a decade of leadership in composite part manufacturing, Rockman Advanced Composites brings unmatched expertise, scalability, and innovation to every project. Whether you’re developing cutting-edge aerospace solutions or looking to redefine automotive efficiency, we serve as your trusted partner in transforming ideas into reality.

Here’s what sets us apart:

- Deep domain knowledge across aerospace, automotive, industrial, and defense sectors

- Flexible production capabilities, from prototypes to high-volume series

- Custom composite formulation and tailored manufacturing techniques

- End-to-end project management with a focus on quality, delivery, and cost optimization

Conclusion: Engineering the Future with Composites

From aircraft to automobiles, wind turbines to wearable tech, precision composite part manufacturing is revolutionizing modern engineering. As demands grow for stronger, lighter, and more sustainable components, composite technologies are rising to meet the challenge.

At Rockman Advanced Composites, we don’t just manufacture parts—we build the future, one fiber at a time.

Ready to transform your next engineering project with precision composite solutions?

Connect with Rockman Advanced Composites today and explore how we can co-create the next generation of high-performance, lightweight components.