The demand for stronger, lighter, and more sustainable materials has never been greater. Across industries—automotive, aerospace, defense, motorsports, and renewable energy—the race is on to develop advanced technologies that push the limits of performance without compromising efficiency. At the heart of this transformation lies a revolutionary material: carbon fiber parts.

Lightweight, incredibly strong, and exceptionally versatile, carbon fiber is unlocking the next frontier in engineering. At Rockman Advanced Composites, we’re not just keeping up with the evolution—we’re driving it.

What Are Carbon Fiber Parts?

Carbon fiber parts are components made from carbon fiber-reinforced polymer (CFRP), a composite material combining carbon fibers with a polymer matrix (usually epoxy, polyester, or vinyl ester resin). The result is a material that offers an unmatched strength-to-weight ratio, stiffness, corrosion resistance, and thermal stability.

Each strand of carbon fiber is five times stronger than steel but significantly lighter. When woven into fabric and molded with a resin, the composite can be shaped into complex structures—ideal for high-performance applications where both form and function matter.

Why Carbon Fiber is the Future of Engineering

Carbon fiber parts have transcended their niche origin in aerospace to become critical in sectors like automotive, marine, sports, defense, and even consumer electronics. Here’s why:

Unparalleled Strength-to-Weight Ratio

Traditional materials like steel or aluminium simply can’t compete with carbon fiber when it comes to weight savings. Components that once relied on heavy metals are now being replaced with lightweight carbon fiber parts that offer the same—or better—performance characteristics.

Exceptional Durability and Fatigue Resistance

Unlike metal, carbon fiber doesn’t rust or fatigue easily. Its long lifecycle makes it a reliable choice for mission-critical applications in aviation and defense where durability is paramount.

Thermal and Chemical Stability

Carbon fiber resists extreme temperatures and aggressive chemicals, making it ideal for high-performance engines, motorsport applications, and harsh operating environments.

Design Flexibility

Carbon fiber parts can be molded into complex, aerodynamic shapes with minimal tooling. This flexibility gives engineers the freedom to innovate, streamline, and optimize every curve and contour of a component.

How Rockman Advanced Composites is Leading the Way

At Rockman Advanced Composites, we bring innovation and precision engineering together to deliver world-class carbon fiber solutions. Our integrated approach—from concept to production—empowers clients with cutting-edge carbon fiber parts that exceed international performance standards.

Capabilities That Set Us Apart:

- State-of-the-art Autoclaves and Curing Technology

- CAD/CAM-Driven Tool Design

- Prototyping and Serial Production

- Multi-Axis CNC Machining

- In-House Testing and Quality Control

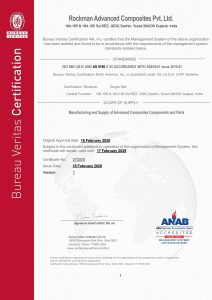

- AS9100D & ISO 9001 Certifications

We cater to both custom, low-volume projects and scalable mass production, making us a preferred partner across industries.

Applications of Carbon Fiber Parts Across Industries

Let’s dive into how different sectors are unlocking the future with carbon fiber technology.

Aerospace and Defense

In aerospace, every gram counts. Carbon fiber parts like fuselage panels, wing structures, and control surfaces are being used to reduce aircraft weight, improve fuel efficiency, and enhance overall flight performance.

In defense, the high strength and radar transparency of carbon fiber materials make them ideal for unmanned aerial vehicles (UAVs), missile components, and armored vehicles.

Automotive and Motorsports

From hypercars to electric vehicles (EVs), the use of carbon fiber parts is revolutionizing transportation. These components not only make vehicles lighter and faster but also improve handling and fuel economy.

In motorsports, where milliseconds count, carbon fiber is the material of choice for body panels, spoilers, suspension components, and monocoques. Its ability to absorb and dissipate energy during crashes also enhances driver safety.

Renewable Energy

Wind turbine blades, traditionally made from fiberglass, are increasingly incorporating carbon fiber to improve strength, reduce weight, and enhance efficiency. Lightweight components also make installation easier and extend the lifespan of wind energy systems.

Medical Devices and Prosthetics

Carbon fiber is biocompatible and incredibly lightweight—making it ideal for prosthetics, surgical instruments, and orthotic supports. It enhances patient comfort without compromising strength or function.

Consumer Electronics and Sporting Goods

From high-end smartphones to performance bicycles and tennis rackets, carbon fiber parts are found in countless consumer products that demand durability, aesthetics, and performance.

Sustainability: The Silent Strength of Carbon Fiber

As industries pivot toward greener alternatives, carbon fiber parts are playing a vital role in building a sustainable future.

- Weight Reduction = Energy Savings: Lighter vehicles and aircraft consume less fuel or battery power.

- Extended Product Lifespan: Carbon fiber’s resistance to corrosion and wear reduces replacement frequency.

- Recyclability and Reusability: Emerging technologies are improving the recyclability of carbon fiber composites, making them more eco-friendly over time.

At Rockman Advanced Composites, sustainability isn’t an afterthought—it’s integrated into our design and production philosophy.

Innovation in Manufacturing: The Rockman Advantage

We employ a variety of advanced manufacturing techniques tailored to meet unique client needs:

Prepreg Layup

Ideal for aerospace-grade quality and dimensional accuracy, using resin-impregnated carbon fiber sheets cured in autoclaves.

Resin Transfer Molding (RTM)

A closed mold process perfect for high-volume, high-strength parts with a smooth finish.

Vacuum Infusion

Cost-effective and scalable for large composite parts, often used in wind and marine industries.

Hybrid Composites

Combining carbon fiber with Kevlar, fiberglass, or metal mesh for optimized strength, stiffness, and impact resistance.

By combining decades of technical know-how with digital innovation and a customer-first mindset, Rockman is redefining what’s possible with carbon fiber parts.

The Road Ahead: Carbon Fiber in Next-Gen Technologies

The future is bright—and lightweight. Here’s where we see carbon fiber headed in the next decade:

Urban Air Mobility (UAM) and Drones

The rise of electric vertical takeoff and landing (eVTOL) aircraft is fueling demand for ultra-light materials. Carbon fiber will be critical in making flying taxis viable and safe.

Electric Vehicles (EVs)

Battery weight remains a challenge. Carbon fiber’s ability to reduce chassis and body weight will help extend EV range and performance.

Additive Manufacturing with Carbon Fiber

3D printing with continuous carbon fiber is revolutionizing rapid prototyping and small-batch manufacturing, bringing agility to product development.

Why Partner with Rockman Advanced Composites?

Choosing the right manufacturing partner can make or break your project. At Rockman Advanced Composites, we don’t just deliver parts—we engineer possibilities.

- Industry Expertise: Decades of experience across automotive, aerospace, and defense.

- Custom Solutions: Tailored engineering and manufacturing services for every project.

- Quality Assurance: World-class facilities certified to the highest industry standards.

- Global Reach, Indian Heart: Proudly headquartered in India, with international capabilities and partnerships.

Whether you’re building the next electric super car, a drone fleet, or a lightweight prosthetic—our advanced carbon fiber parts are the future-ready solution you need.

Final Thoughts

Lightweight engineering is no longer a luxury—it’s a necessity in a world demanding higher performance, energy efficiency, and sustainability. Carbon fiber parts are at the core of this transformation, enabling engineers and innovators to do more with less.

At Rockman Advanced Composites, we’re proud to be at the forefront of this revolution. Our commitment to excellence, innovation, and partnership ensures that we continue to unlock new possibilities for a lighter, stronger, and more sustainable future.

Let’s engineer tomorrow—today.

Explore more at Rockman Advanced Composites