The global carbon parts market is expected to grow from USD 19.8 billion in 2022 to USD 60.5 billion by 2030, mainly due to rising fuel prices and stringent regulations on vehicle emissions. Because of these factors, carbon fiber has become a material of choice for many carbon parts suppliers because of its exceptional strength-to-weight ratio. Carbon parts are an excellent replacement for conventional metals that significantly reduce the weight of the vehicle. This also results in improved engine performance and fuel efficiency because carbon fiber is twice as strong as conventional metals. With the growing focus on environmental sustainability, OEMs are increasingly making use of carbon parts, which are gaining prominence in the automotive sector because of their high impact resistance, superior modulus, easy recycling, and corrosion resistance.

Key Industries Leveraging Carbon Parts

OEMs are expanding the technological innovation horizons within the automotive sector to improve the performance, safety, and efficiency of vehicles. The use of carbon fiber parts is the latest innovation that is encouraged by both OEMs and suppliers to produce and supply precision-engineered carbon parts to diverse industries. OEM carbon parts suppliers are catering to these key industries

Automotive – Carbon fiber is an extremely lightweight material that is high in strength. Due to these characteristics, the material is used to design automotive parts that deliver enhanced performance in automotive applications. Currently, automakers are finding innovative ways to leverage OEM carbon parts to help reduce vehicle weight and improve efficiency. Today major high-end automotive companies and carbon parts manufacturers and suppliers are partnering to popularize carbon parts in the automotive sector.

Aerospace – The aerospace industry was among the first few sectors to make use of carbon parts, mainly to reduce the weight of the aircraft. Major aircraft companies are integrating carbon parts in wings, fuselage sections, and other vital components to reduce the overall weight. Thus, leading carbon parts suppliers are playing an integral role in catering to the high performance and safety requirements set by aerospace OEMs.

Sports Equipment – Besides, automotive and aerospace, carbon parts suppliers are also catering to the demands of the sports industry, where OEMs demand high-strength and lightweight materials for manufacturing sports equipment like tennis rackets, skis, and bicycles. Leading and reliable carbon parts suppliers associate with reputed sporting brands to deliver quality carbon parts for manufacturing high-end sporting equipment.

Characteristics of an Ideal Carbon Parts Supplier

Carbon fiber has emerged as the most sought-after material due to its durability and high strength-to-weight ratio. Nevertheless, industries need to choose the best carbon parts supplier to ensure that they partner with a supplier that caters to their high standard and top-quality parts requirements.

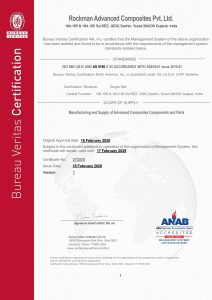

Quality Control – It is vital to pick a trusted carbon parts supplier that has a well-documented quality control system and who carries out regular audits, product inspections, and process validations to maintain high standards. The supplier should hold relevant certifications to ensure that they adhere to a comprehensive quality management system covering all aspects of production from material handling to final inspection.

Advanced Manufacturing Capabilities – While selecting manufacturers and suppliers of carbon fiber parts, industries should always consider advanced manufacturing capabilities, as the manufacturing process of carbon fiber parts affects their qualities and performance. The manufacturer and supplier should possess advanced capabilities like continuous compression molding, flat consolidation, traditional tool forming, and CNC machining to produce parts that are not only lighter and stronger but even uniform and consistent in quality.

Scalability and Customization – Automotive manufacturers need carbon parts suppliers that can efficiently meet their production requirements and can also provide customized carbon parts meeting their requirements. A supplier who can efficiently cater to the requirements of high-performance carbon parts requirements for luxury cars to carbon parts requirements of the aerospace industry should be preferred by the industries.

Strong R&D Capabilities – Innovation is crucial in the carbon parts field, and hence manufacturers and suppliers with in-house research teams can produce the latest and innovative carbon parts that can bring transformation in major industries. Many suppliers collaborate directly with OEMs through joint innovation programs, to ensure that new products meet specific performance standards.

Future Outlook: A Growing Market with Opportunities

As manufacturing technologies evolve, the relationship between OEMs and carbon parts suppliers will strengthen and deepen. With advances in carbon parts manufacturing and recycled carbon fiber solutions, industries will unlock new opportunities for sustainable growth. Moreover, emerging industries are expected to drive further demand for lightweight carbon components. These trends align with the broader goals of Industry 4.0, combining data-driven production with sustainable innovation.

Recap

Carbon parts suppliers play a pivotal role in helping OEMs achieve their goals of lightweight design, improved efficiency, and environmental sustainability. As demand continues to grow across automotive, aerospace, and other sectors, these partnerships will become even more critical. By focusing on advanced manufacturing capabilities, sustainability, and R&D, suppliers can position themselves as indispensable partners in the evolving manufacturing landscape.